XIONGQIAN Perforated Metal Strip

Perforated metal strips are made up of a metal sheet. It has been punched with a series of uniform holes. It is a great choice for businesses. Especially if you’re looking for a high-quality material that can be used to complete custom projects.

XIONGQIAN offers various sizes and patterns for perforated strips. We ensure they fit your application. Additionally, we made them strong enough to withstand the toughest conditions. You can also import custom Metal Windbreak and Perforated Aluminum Sheet from us.

Contact us today to learn more about how our perforated metal strips can help you get the job done!

Different Perforated Metal Strips for Wholesale

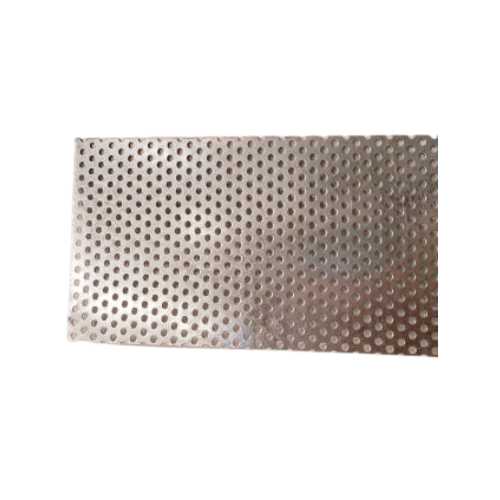

It has been cut with a round hole pattern. The strips are often used in industrial applications. Typically in order to filter, separate, or protect materials.

These strips have been punched or cut to create small hole patterns. Often add a decorative touch to furniture, walls, and other surfaces.

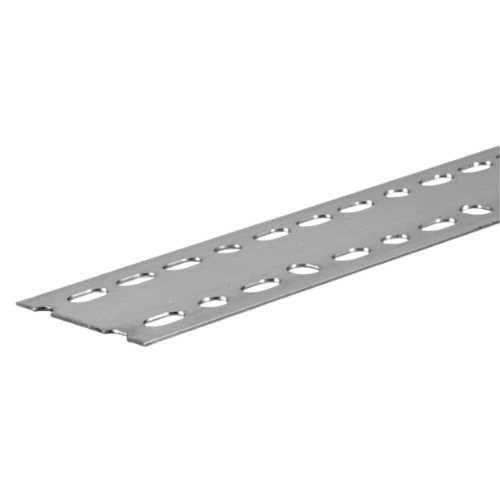

Thin metal strips that have been cut with various hole sizes. These are used in protecting and reinforcing walls. Provides support for various objects.

Metal strips that have been punched, cut, or rolled. This can create patterns of small, regularly spaced holes. They are used in a variety of industrial applications.

Come with a perforated pattern of slots and holes. These metal strips are used in a variety of applications, including filtration, ventilation, and sound insulation.

Designed with hexagonal holes punched into them. These strips are used in filtration, air diffusers, etc. And can be made of aluminum, steel, and more.

Why Choose XIONGQIAN Perforated Metal Strip

Increased security and privacy. The strips can provide an effective and stylish way to keep your business safe.

Improved acoustics. You can create sound absorption and reduce noise levels in certain areas of your business.

Enhanced aesthetics. You will have eye-catching patterns. Definitely, it can add a touch of style to your business.

Increased brand recognition. Create an eye-catching logo with them. Therefore you will increase brand recognition.

Related Products

Standard Measurements of Perforated Metal Strip

| Thickness | 0.03 inches |

| Length | 12 inches |

| Width | 0.25 inches |

| Hole Size | 0.125 inches |

| Hole Spacing | 0.25 inches |

How Perforated Metal Strips are Produced

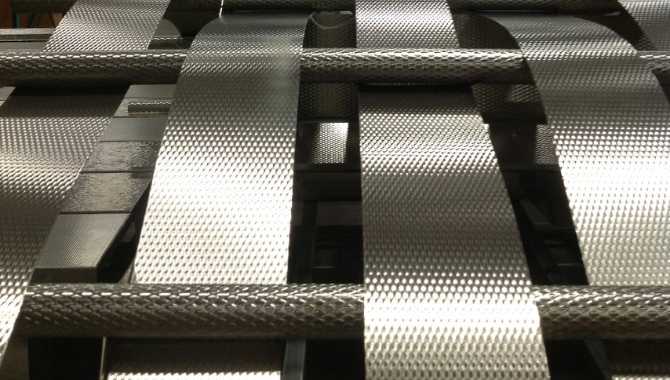

A variety of methods are utilized. The most common method involves using a perforating press to punch out hundreds of small holes in a metal sheet. The press can be programmed to create various hole sizes and shapes.

Once the holes are punched out, the strip is then cut to your specified length.

Metal Selections

The perforated metal strips can be made from:

- Stainless steel

- Aluminum

- Copper

- Brass

- Bronze

- Or as per your requests

List of Applications:

Filtration. The strips are often used as a filter in a variety of industries such as food processing, automotive, and chemical production.

Decorative. It can be used as decorative elements in interior design, such as screens and partitions.

Air Filtration. They are often used in air conditioning and ventilation systems as a filter for airborne particles.

Structural Support. Ideal structural element in buildings and bridges.

Architectural Design. Widely used to create decorative architectural features such as sunshades and balconies.

Industrial Use. Used in industrial applications as a way to reduce noise, improve airflow, and prevent dust from entering the work area.

Range of Finishes We Offer

- Unpainted/Mill finish: The most basic finish of all perforated strips and is the standard finish.

- Anodized: Created by an electrochemical process that creates a hard coating on the strip surface. This finish is used when increased corrosion resistance is needed.

- Powder Coated: This finish involves applying a powder coating to the strip and then curing it with heat. The coating provides a durable protective finish. Available in a variety of colors.

- Galvanized: Galvanized steel strip has been coated with a thin layer of zinc, which provides corrosion and rust resistance.

- Pre-painted: Pre-painted metal strip has been painted with a base coat and a top coat. This finish provides a durable and uniform color.

FAQ on Perforated Metal Strip

How long-lasting these strips are?

The perforated metal strip can last for many years, depending on the type of metal used and the environment it is in. Generally, galvanized steel and stainless steel are the most durable materials for perforated strips. These metals can last for up to 20 years in most environments.

Are there any limitations to the size of perforated metal strips?

Strip size is limited by the machine size used to punch the holes. Generally, perforated strips can be made up to 48 inches wide and 120 inches long.

What are the holes patterns available?

They come in a variety of patterns, including round, square, rectangular, and triangular holes.